In an article published last year, Ken Kwong's group announced a new method for performing cerebrovascular reactivity measurements using breath holds. This "breath-by-breath exchange ratio" method was shown to be as good as the gold standard endogenous CO2 stimulus method for CVR:

Over the past few months, my colleagues and I have been working on a way to replicate this method using BIOPAC hardware. Our facility has already been using the BIOPAC system to record physiological data from our subjects so incorporating these new features into our existing setup would be the smoothest option. If you're interested in building your own setup, either from scratch or you already have a BIOPAC unit on hand, this post will outline the equipment purchased and the design we came up with While it does require a bit of work to put together, it is simple to use and the physiological data it records should benefit all fMRI researchers

BIOPAC and Acqknowledge

BIOPAC has been our go-to system for recording physiological data for quite some time. The MP150 model we have has been discontinued and replaced with the MP160. In addition to the base system, two additional modules must be purchased, these are the O2100C and the CO2100C. The company states the modules can be used on both the MP150 and the MP160, so it should not matter which one you have. For reference we use version 5.0.2 of their proprietary software Acqknowledge on a non-networked PC running Windows 7.

Booster Pump

If only all we had to do was buy extra modules and some tubing, but alas a booster pump must be added to the gas sampling line when sampling from a scanner that is around 30ft away from the BIOPAC. The booster pump permits the O2 and CO2 modules to be run in parallel. The onboard pumps in the O2 and CO2 modules simply aren't powerful enough on their own. A parts list is provided below with some links. If there is no link then that means we used spare parts that were lying around our electronics shop, so hopefully if you are looking to construct this yourself then you also have similar access.

- Pump

- wires

- Power supply

- 4x4 container box

- ON/OFF switch

- Wire

- 5V LED

Consult the pump datasheet for information on the electrical connections required. If you decide to buy a different pump then make sure to follow those instructions instead. Some basic knowledge of electronics, electric circuits, and soldering is required for completing this portion, but the final result may look something like ours.

We did not want our booster pump to be on 24/7, possibly decreasing its lifespan, so we included an LED light and a power switch to control it. While advised, this is optional if you wish to simplify the pump design some. Once the booster pump is ready we can move on to connecting everything via tubing.

Connections

With the parts purchased and the pump assembled, it's time to bring the entire setup together. First connect the MP150/MP160, the O2100C, and the CO2100C to each other and to your PC according to BIOPAC's guidelines and specifications.

The following is a list of parts that we used to connect the modules to the pump and then to connect the pump to the nasal cannula:

- Filters (*see Note 1)

- Drying tubes

- 1/8" ID (inner diameter) thick wall tubing

- MRI tubing from BIOPAC (*optional - see Note 2)

- Luer fittings - female to 1/8" hose barb

- Luer fittings - male to male

- Luer fittings - female to female tee

- Luer fittings - one way check valve

- Nasal cannula (*See Note 3)

Similar to when we assembled the pump, the 1/8" ID tubing we used here was on hand in our facility. If you are ordering some make sure to obtain enough length to go from the front of your BIOPAC, through a wave guide, and into the bore of the magnet. The specific tubing is not important, just make sure the inner diameter is 1/8" so it mates up with the lure fittings. You're going to end up cutting a few pieces so make sure to have a knife handy. The following diagram shows all components, including connectors and filters.

|

| Figure 3 - Connections diagram showing modules, booster pump, tubing, and connectors |

The following images break down the connections into smaller sections so you can see our finished product. We connected the filters directly to the front of the modules via the intake ports. The pieces of electrical tape are used for color coding in case something ever happens to get disconnected. You can also use the color coding to cross-reference the schematic in Figure 3 to the photos below.

|

| Figure 4, 5 & 6 - Modules, filters, tubing, connectors, pump, one way valves, etc! |

Assuming your setup is similar to what is outlined above then the next step is to begin acquiring and recording data via Acqknowledge.

Recording in Acqknowledge

Before you begin recording you must turn on the BIOPAC unit, make sure the settings on the front of the modules are correct (For the O2100C you want the gain set to 20% and for the CO2100C set it to 10%), turn on their pumps (via front switch), turn on the booster pump, and attach a new nasal cannula to the end of the tubing.. The module pumps take a few minutes to warm up, so readings may be inconsistent at first (*see Note 1, on calibration)

Open the Acqknowledge template that you will be using. Assuming the BIOPAC system AND the modules have been setup and added properly (*see Note 4) you should see a screen similar to the ones shown below. Either you are recording multiple other physio channels like pulse and respiration (left), or you are only recording %CO2 and %O2 (right).

|

| Figures 7 & 8 - Acqknowledge showing five channels and showing two channels |

And there you have it! Recording end-tidal CO2 and O2 using BIOPAC! Now all that's left is to finish out your scanning session, save the Acqknowledge data file, remove the subject's nasal cannula from the tubing (*see Note 6), and turn off all pumps (*see Note 7) and that's it.

While purchasing BIOPAC and the two modules is not cheap, the rest of the setup is fairly inexpensive to replicate. Hopefully the benefits of acquiring such data convince you to build this yourself. Not only is the data valuable, it is easy to acquire regularly once the initial setup is complete.

Additional Notes

Note 1: BIOPAC suggests changing the filters every month. They also suggest the O2100C and CO2100C modules be calibrated before every session. Reading through their documentation, this seems to be due to barometric pressure and water vapor pressure (humidity). The former will affect the absolute level of gas flow, while the latter will affect the absorption of CO2- and O2-specific wavelengths. The sensors use an optical filter so presumably there could be overlap between the absorption spectrum of water, CO2 and O2 in some way. Our staff chose to at first monitor the measurements during the first months of use to see just how much barometric pressure and humidity cause them to change or fluctuate. California weather patterns tend to shift slowly, so we may not see anything substantial unless we get a rapid change in weather. If using the peak O2 and CO2 numbers to define end-tidal values then the calibration is probably not critical.

Note 2: Our facility had some of BIOPAC's tubing so we incorporated it into the setup, but it is not required. Use your own 1/8" ID tubing if you have it.

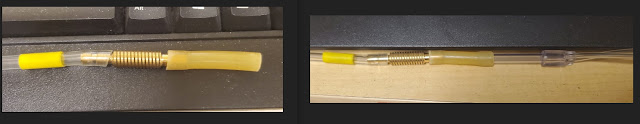

Note 3: For our work we wanted to use nasal cannulas, not face masks, for comfort, compliance and simplicity. It's entirely possible to use a face mask in case there's concern of missing mouth breathing. Regardless of your choice, make sure it mates up properly to the tubing. For example we purchased some nasal cannula with a hard plastic connector that did not mate up properly so we had to place a brass connector and some extra pliable tubing, as you can see below. Don't be afraid to improvise!

|

| Figure 10 & 11 - 1/8" tubing with brass connector, pliable tubing and nasal cannula |

Note 4: Consult your Acqknowledge and BIOPAC user manuals or contact their customer service if you have trouble setting this up. When collecting %O2 and %CO2 recordings, the main issue to be aware of with the Acqknowledge software is verifying that the modules are setup and recognized as modules rather than simply channels. This may seem like a minor detail, but improper setup results in the values for these readings being reported in volts rather than actual percentage of O2 and CO2. It’s easy to see whether you are using the wrong setup by looking at the right side of the screen. In the example below, If you see “Volts” rather than “%O2” and “%CO2” then the setup is incorrect. Also keep in mind that we record all physiological data we collect at 125 Hz.

Note 5: For a fixed pump speed, the total delay depends primarily on the length of tubing between the BIOPAC and the cannula. Testing at our facility showed this delay to be around 33 seconds. This will vary depending on your location and you should determine this value during initial setup. Also check it periodically, just in case the pump efficiency decays over time.

Note 6: - If you are keeping the cannula for further use on the same subject, consider washing or disinfecting then placing it in a plastic bag when dry.

Note 7 : Similar to our booster pump, it's probably best to not keep the O2100C and CO2100C pumps on at all times so as not to diminish their lifespan. If you keep your BIOPAC unit on at all times, consider putting the pumps on a separate power strip.